ISO 9001:2015 Certified professional pneumatic tools, gear reducer, torque tool, wireless torque transducer manufacturer and supplier from Taiwan

Redefining Industrial Assembly

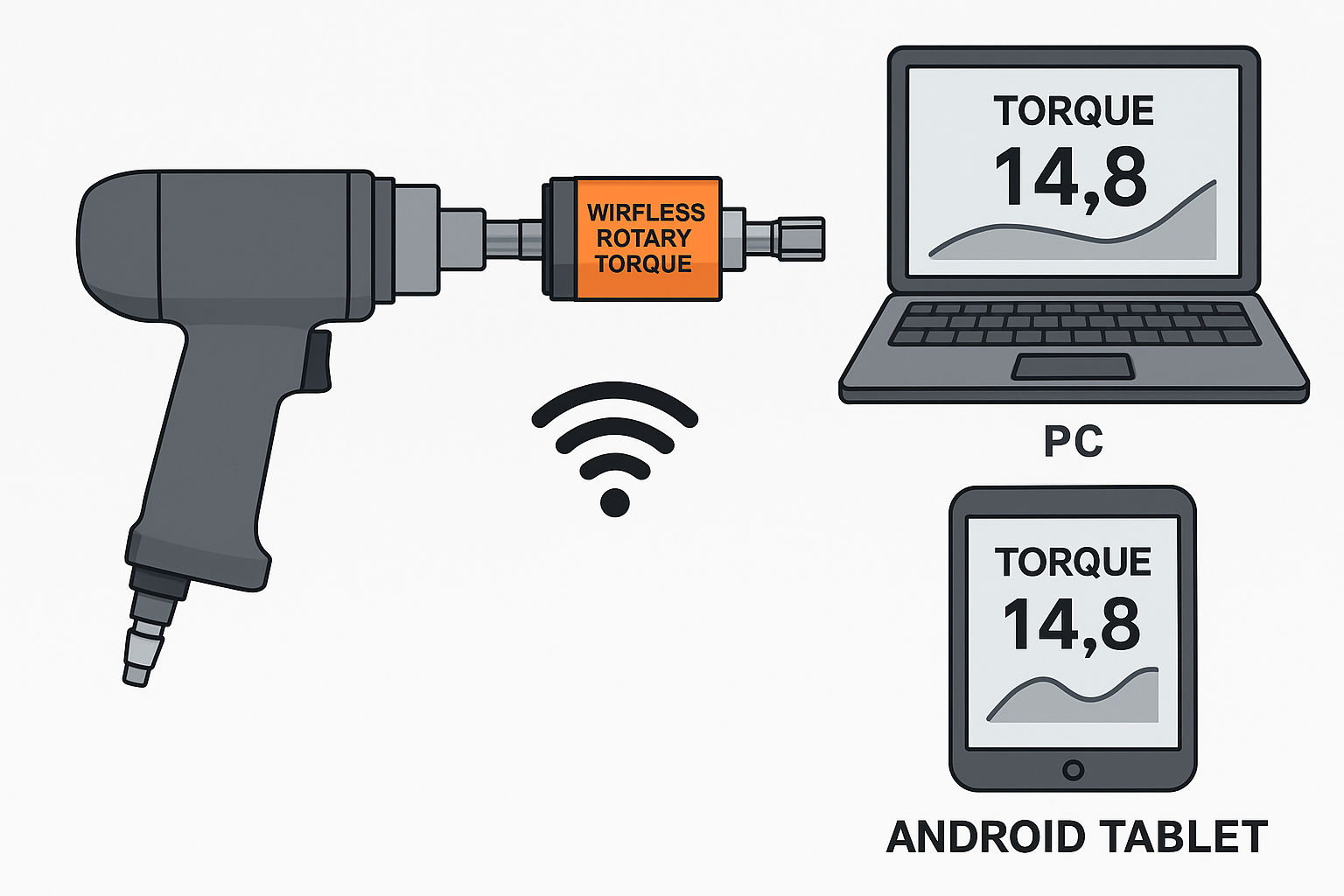

At our core beats the relentless drive for innovation, fueling our focus on revolutionizing torque control technologies and precision fastening systems. With a legacy spanning over two decades, we’ve honed our expertise in integrating these cutting-edge advancements into industrial assembly air pneumatic tools and cordless counterparts.

Our story