Average Free Air consumption of some common air tools are indicated in the table below. The air consumption is based on the commonly used working pressure of approximately 90 psi (620 kPa, 6.2 bar).

| Air Tool/Equipment | Average Free Air Consumption (cfm) |

| Air Bushing | 20 |

| Air Filter Cleaner | 3 |

| Air Hammer, light | 4 |

| Air Hammer, heavy | 22 |

| Air Hoist, 1000 lb | 5 |

| Air Motor – 0.5 hp | 6 – 10 |

| Air Motor – 1 hp | 12 – 15 |

| Air Motor – 2 hp | 18 – 20 |

| Backfill Tamper | 30 – 35 |

| Bead Breaker | 12 |

| Bench Rammer | 5 |

| Brad Nailer | 0.5 |

| Blow Gun | 3 |

| Body Polisher | 2 |

| Body Orbital Sander | 5 |

| Brake Tester | 4 |

| Burr Tool, small | 4 |

| Burr Tool, large | 5 – 6 |

| Bus Lift | 6 |

| Car Lift | 6 |

| Carbon Remover | 3 |

| Carving tool | 10 – 15 |

| Caulking Gun | 4 |

| Chain Saw | 7 – 22 |

| Chipping Hammer | 30 – 40 |

| Chisel Hammer | 3 – 10 |

| Circle Saw – 8 inch | 12 |

| Circle Saw – 12 inch | 17 |

| Compression Riviter | 1 |

| Concrete Vibrator | 20 – 50 |

| Demolition Tool | 30 – 40 |

| Cut-Off Tool | 4 – 10 |

| Die Grinder 1/4″ | 4 – 6 |

| Disc Grinder – 7″ | 5 – 8 |

| Drill, Reversible or Straight-Line | 3 – 6 |

| Drill 3/8″ | 4 |

| Drill 1/2″ | 4 |

| Dust Blow Gun | 3 |

| File/Saw Machine | 3-5 |

| Floor Rammer | 7 |

| Framing Nailer | 2.5 |

| Garage Door, Pneumatic | 3 |

| Grease Gun | 4 |

| Grinder 2 in Horizontal | 5 – 10 |

| High Speed Grinder | 8 |

| Hoists, 1 ton | 1 |

| Hydraulic Riveter | 4 |

| Hydraulic Lift, 8000lb | 6 |

| Hydraulic Floor Jack | 6 |

| Impact Driver 1/2″ | 4 |

| Impact Driver 3/4″ | 7.5 |

| Impact Driver 1″ | 12 |

| Impact Wrenches – 3/8″ | 2 – 5 |

| Impact Wrenches – 1/2″ | 4 – 5 |

| Impact Wrenches – 1″ | 10 |

| Jackhammer, medium | 135 |

| Jitterbug Sander | 6 |

| Lift, Bus or Truck | 10 |

| Lift, Car | 6 |

| Mini Die Grinder | 4 – 6 |

| Nailer, Brad (30 psi) | 2 |

| Nailer, Framing (50 psi) | 4 |

| Needle Scaler | 8 – 16 |

| Nibbler | 4 |

| Nutsetter – 3/8″ inch | 3 – 6 |

| Nutsetter – 3/4″ inch | 5 – 8 |

| Orbital Sander | 6 – 9 |

| Paint Sprayers, production gun | 20 |

| Paint Sprayers, Small Hand Operated | 3 – 7 |

| Pavement breaker | 35 – 60 |

| Pneumatic doors | 2 |

| Rammers – small | 3 |

| Rammers – large | 10 |

| Ratchet, 1/4″ | 3 |

| Ratchet, 3/8″ | 4 |

| Rivet Buster | 40 – 50 |

| Rock Drill | 100 |

| Rotational Sander | 8 – 15 |

| Sand Blasters | 6 – 400 |

| Sander, Dual | 11 – 13 |

| Screwdriver | 1 – 6 |

| Shears | 8 – 16 |

| Spark plug cleaner | 5 |

| Speed Saw | 5 |

| Spray Cleaner | 5 |

| Spray gun, Basic (20 – 45 psi) | 0.5 – 3.5 |

| Spray gun, Commercial (30 – 70 psi) | 4 – 7 |

| Spring Oilers | 4 |

| Strait line Sander | 4 – 7 |

| Tapper – 3/8″ inch | 3 – 5 |

| Tire Changer | 1 |

| Tire Inflation | 2 |

| Transmission flusher | 3 |

| Upholstery Stapler (30 psi) | 2 |

| Vacuum Cleaners | 6 |

| Valve Grinders | 2 |

| Air Tool/Equipment | Average Free Air Consumption Liter/s |

| Air Bushing | 20 8 |

| Air Filter Cleaner | 3 1.2 |

| Air Hammer, light | 4 1.6 |

| Air Hammer, heavy | 22 8.8 |

| Air Hoist, 1000 lb | 5 2 |

| Air Motor – 0.5 hp | 6 – 10 2.4 – 4 |

| Air Motor – 1 hp | 12 – 15 4.8 – 6 |

| Air Motor – 2 hp | 18 – 20 7.2 – 8 |

| Backfill Tamper | 30 – 35 12 – 14 |

| Bead Breaker | 12 4.8 |

| Bench Rammer | 5 2 |

| Brad Nailer | 0.5 0.2 |

| Blow Gun | 3 1.2 |

| Body Polisher | 2 0.8 |

| Body Orbital Sander | 5 2 |

| Brake Tester | 4 1.6 |

| Burr Tool, small | 4 1.6 |

| Burr Tool, large | 5 – 6 2 – 2.4 |

| Bus Lift | 6 2.4 |

| Car Lift | 6 2.4 |

| Carbon Remover | 3 1.2 |

| Carving tool | 10 – 15 4 – 6 |

| Caulking Gun | 4 1.6 |

| Chain Saw | 7 – 22 2.8 – 8.8 |

| Chipping Hammer | 30 – 40 12 – 16 |

| Chisel Hammer | 3 – 10 1.2 – 4 |

| Circle Saw – 8 inch | 12 4.8 |

| Circle Saw – 12 inch | 17 6.8 |

| Compression Riveter | 1 0.4 |

| Concrete Vibrator | 20 – 50 8 – 20 |

| Demolition Tool | 30 – 40 12 – 16 |

| Cut-Off Tool | 4 – 10 1.6 – 4 |

| Die Grinder 1/4″ | 4 – 6 1.6 – 2.4 |

| Disc Grinder – 7″ | 5 – 8 2 – 3.2 |

| Drill, Reversible or Straight-Line | 3 – 6 1.2 – 2.4 |

| Drill 3/8″ | 4 1.6 |

| Drill 1/2″ | 4 1.6 |

| Dust Blow Gun | 3 1.2 |

| File/Saw Machine | 3-5 1.2 |

| Floor Rammer | 7 2.8 |

| Framing Nailer | 2.5 1 |

| Garage Door, Pneumatic | 3 1.2 |

| Grease Gun | 4 1.6 |

| Grinder 2 in Horizontal | 5 – 10 2 – 4 |

| High Speed Grinder | 8 3.2 |

| Hoists, 1 ton | 1 0.4 |

| Hydraulic Riveter | 4 1.6 |

| Hydraulic Lift, 8000lb | 6 2.4 |

| Hydraulic Floor Jack | 6 2.4 |

| Impact Driver 1/2″ | 4 1.6 |

| Impact Driver 3/4″ | 7.5 3 |

| Impact Driver 1″ | 12 4.8 |

| Impact Wrenches – 3/8″ | 2 – 5 0.8 – 2 |

| Impact Wrenches – 1/2″ | 4 – 5 1.6 – 2 |

| Impact Wrenches – 1″ | 10 4 |

| Jackhammer, medium | 135 54 |

| Jitterbug Sander | 6 2.4 |

| Lift, Bus or Truck | 10 4 |

| Lift, Car | 6 2.4 |

| Mini Die Grinder | 4 – 6 1.6 – 2.4 |

| Nailer, Brad (30 psi) | 2 0.8 |

| Nailer, Framing (50 psi) | 4 1.6 |

| Needle Scaler | 8 – 16 3.2 – 6.4 |

| Nibbler | 4 1.6 |

| Nutsetter – 3/8″ inch | 3 – 6 1.2 – 2.4 |

| Nutsetter – 3/4″ inch | 5 – 8 2 – 3.2 |

| Orbital Sander | 6 – 9 2.4 – 3.6 |

| Paint Sprayers, production gun | 20 8 |

| Paint Sprayers, Small Hand Operated | 3 – 7 1.2 – 2.8 |

| Pavement breaker | 35 – 60 14 – 24 |

| Pneumatic doors | 2 0.8 |

| Rammers – small | 3 1.2 |

| Rammers – large | 10 4 |

| Ratchet, 1/4″ | 3 1.2 |

| Ratchet, 3/8″ | 4 1.6 |

| Rivet Buster | 40 – 50 16 – 20 |

| Rock Drill | 100 40 |

| Rotational Sander | 8 – 15 3.2 – 6 |

| Sand Blasters | 6 – 400 2.4 – 160 |

| Sander, Dual | 11 – 13 4.4 – 5.2 |

| Screwdriver | 1 – 6 0.4 – 2.4 |

| Shears | 8 – 16 3.2 – 6.4 |

| Spark plug cleaner | 5 2 |

| Speed Saw | 5 2 |

| Spray Cleaner | 5 2 |

| Spray gun, Basic (20 – 45 psi) | 0.5 – 3.5 0.2 – 1.4 |

| Spray gun, Commercial (30 – 70 psi) | 4 – 7 1.6 – 2.8 |

| Spring Oilers | 4 1.6 |

| Strait line Sander | 4 – 7 1.6 – 2.8 |

| Tapper – 3/8″ inch | 3 – 5 1.2 – 2 |

| Tire Changer | 1 0.4 |

| Tire Inflation | 2 0.8 |

| Transmission flusher | 3 1.2 |

| Upholstery Stapler (30 psi) | 2 0.8 |

| Vacuum Cleaners | 6 2.4 |

| Valve Grinders | 2 0.8 |

Ratings based on a 25% load factor – tools running 25% of the time.

- 1 psi (lb/in2) = 6,894.8 Pa (N/m2) = 6.895×10-3 N/mm2 = 6.895×10-2 bar

- 1 cfm (ft3/min) = 1.7 m3/h = 0.47 l/s

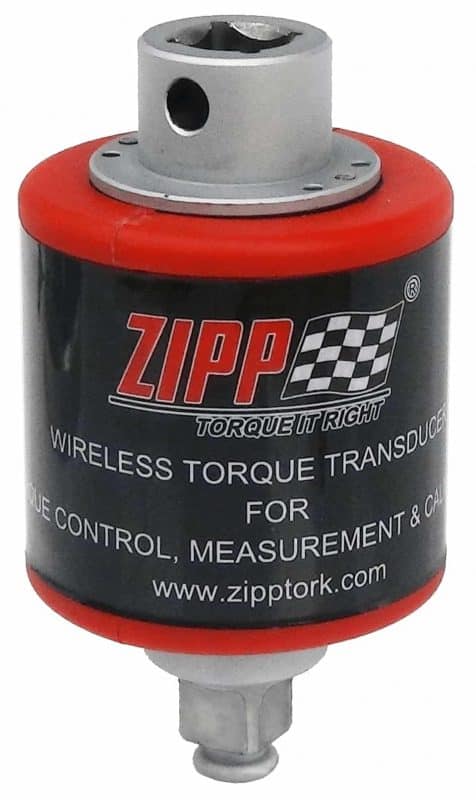

Torque Control System – Industrial 4.0

Torque Control System – Industrial 4.0